25+

Workshops

300+

Projects

100+

Invited Talks

Recent Workshops & Events

Important Projects

Design and Fabrication of Unmaned EV

Project Members: Mechanical and CSE team students

Guides / Investigators : Dr. Mukesh Patil

The final Year students of Mechanical Engineering of 2024 Batch have developed an electric vehicle which has the capability of running in autonomous condition. This vehicle helps in transportation of persons and commodities with more safe and controlled condition. This type of vehicle has huge application in industry/University Campus/Social field.

Smart Hybrid System for 2 wheeler Vehicle

Project Members: Dhanraj Chaitanya, Charan Betta, Deepak S, Jayasimha D

Guides / Investigators : Mrs. Viraja Desphande

An inventive system for a two-wheeler vehicle has been developed by the final-year Mechanical Engineering students of the 2024 Batch. It analyzes the vehicle's speed and can switch between electric and gasoline modes while it is operating. This technique saves energy and lessens a significant reliance on fuels.

Design and Fabrication of Electric wheel Chair for Physically Challenged

Project Members: Pranav Moro, Ritwik Nidamarthy, S Prathik, Varun O V

Guides / Investigators : Dr. Mukesh Patil

Final Year Students of Mechanical Engineering of 2024 batch Designed and Fabricated an Electric Wheel Chair for physically challenged. It facilitates users' mobility and allows them to live their life as they see fit. When compared to manual self-propelled wheelchairs, motorized electric wheelchairs have many advantages, such as less muscle strain and fatigue, improved postural support, and increased comfort over extended use.

Design and Fabrication of Mono Rail

Project Members: Mihir M Savanur, Charan H N, Yathish C G, Shashank S Tambralli

Guides / Investigators : Mr. Sunil B Lakkundi

Final Year Students of Mechanical Engineering of 2024 batch Designed and Fabricated a Mono rail. This monorail system is a dependable kind of transportation that satisfies society's demands for improved environmental consciousness and connectedness. This monorail is quick, secure, hygienic, appealing, and built to handle the demanding tasks of mass travel.

Design and Fabrication of Dual Nozzle 3D Printer

Project Members: Varun, Talha Ahmed, Vishal, Vijay Kumar

Guides / Investigators : Dr. Mukesh Patil

Final Year Students of Mechanical Engineering of 2024 batch Designed and Fabricated a Dual Nozzle 3D Printer. This 3D printer can print the components by supplying two different materials at the same time trough two nozzles. This kind of printers helps to create components with desired properties and shape.

Design and Fabrication of Vegetable Storage Container

Project Members: Anuragh Kamath, Bharath B M, Chandan Raj S, Mohammed Mujtahid

Guides / Investigators : Dr. Bharath Kumar S

A new container for storing vegetables has been designed by the 2024 batch of mechanical engineering final-year students. One benefit of this container is that it keeps veggies fresh for a longer period of time and allows them to be stored at a specific temperature. Even vegetables like onions can be kept in this container.

Design and Fabrication of Multipurpose Agricultural Machine

Project Members: Nayana Sebastian, Mohammed Fawaz Ahmed, Vishal P, Yathish N

Guides / Investigators : Dr. Bharath V

A new Machine for different agricultural operations has been designed by the 2024 batch of mechanical engineering final-year students. This machine helps farmers by decreasing physical work, cutting down on the time and effort needed for different agricultural operations, and increasing total productivity, it fosters efficiency. This machine contributes to the rural economy by enabling farmers to increase efficiency in more agricultural task.

Design and Fabrication of Agricultural waste and Areca Nut Collector

Project Members: Srinivas, Yatish, Yashwant, Raguveera

Guides / Investigators : Shivaraj Dharennavar

A new Machine for different agricultural waste and crop collection has been designed by the 2024 batch of mechanical engineering final-year students. With the help of this machine, farmers can easily collect crop wastes like maize stalks, wheat straw, soybean residues, and more, converting them into useful stock materials for animal bedding and soil enhancement.

Design and Fabrication of Automatic River Cleaning Machine

Project Members: Prajwal P Gowda, Rohit J S, Revanna Gowda, Punith Kumar

Guides / Investigators : Mr. Sunil B Lakkundi

Final Year Students of Mechanical Engineering of 2024 batch Designed and Fabricated a river or lake cleaning Machine. With the help of this large areas of a river can be cleaned quickly and reliably with an automated river cleaning machine, which has several advantages over traditional manual cleaning techniques. These advantages include increased efficiency, lower labor requirements, improved worker safety, the ability to reach difficult-to-access areas, continuous operation, environmental friendliness, and data collection capabilities for water quality monitoring.

Design and Fabrication of Automatic electric pesticide sprayer

Project Members: Sachin, Sagar and Shrishail Badiger

Guides / Investigators : Mr. Sunil B Lakkundi

Final Year Students of Mechanical Engineering of 2024 batch designed and Fabricated a automatic electric pesticide sprayer by which farmers can benefit in a number of ways like spraying, they can cover a larger land area. They have the ability to change the spray's height. They can be used to manage plant diseases, mites, and insects. Chemical herbicides or weed killers can be used to control weeds.

Design and Fabrication of Automated load carrying bogie

Project Members: Sai Preetam reddy, Sadashiva Galag, Rohith S and Lohitesh K M

Guides / Investigators : Mrs. Annapoorna K

The designed and Fabricated automated load carrying bogie has many benefits, such as increased productivity and efficiency, lower labor costs, improved safety, increased accuracy, flexibility in movement, the ability to operate in all terrains, round-the-clock operation, and less downtime. By automating the transportation of loads, workflows become more efficient and human intervention in material handling is reduced.

Design and Fabrication of Compost Machine

Project Members: Charan M, Jeevan Kumar, Pavan T V, Vishal B C

Guides / Investigators : Mr. Sunil B Lakkundi

The final year students of 2024 batch designed and fabricated a composting machine that aids in the production of vital nutrients and bacteria that are advantageous to plants. It makes plants more disease-resistant and aids in the development of stronger root systems.

Design and Fabrication of Multi pUrpose Electric Vehicle

Project Members: Dhanush S, Gireesha N J, Rohan D and Tejas M

Guides / Investigators : Mr. Shivaraj Dharennavar and Mr. Sunil B Lakkundi

The project's primary goal is to design and fabricate an electrical multifunctional agricultural vehicle that can carry out several important agricultural tasks, including leveling, spraying, grass cutting, seeding, and plowing.

Design and Fabrication of Salt Water Desalination

Project Members: Dinesh K S, Hithesh K R and Dheeraj Rathod

Guides / Investigators : Mr. Sunil B Lakkundi

The final year students of 2024 batch fabricated a salt desalination machine which offering a dependable supply of fresh water in places where there is a shortage, combating droughts, expanding the water supply, generating extraordinarily pure water, having the potential for a variety of uses, and being able to augment current freshwater sources, especially in desert locations.

Latest Events

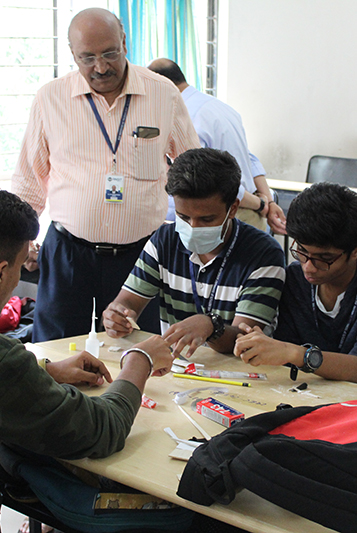

Boot Camp 2024

Department Mechanical Engineering organized a Boot Camp event to provide students a hands-on experience on assembly and disassembly of the two wheeler.

Hi-Fi with Alumni

Department Mechanical Engineering organized an event Hi0fi with alumni to get the previous batch graduates to meet the young students of the department and exchange their thoughts and experiences.

Project Expo

Department Mechanical Engineering hosted a project expo which helps students to exhibit the projects prepared by the final year and pre final year students.

Workshop on Additive Manufacturing for RNSIS School Students

Department Mechanical Engineering organized a workshop for RNSIS school students to get them introduced to the current emerging technology, 3D printing, at the basic level.

SDP on Additive Manufacturing

Department Mechanical Engineering organized a Student development program on Additive Manufacturing for second and third year students to get them introduced to the current emerging technology from industry experts.

Skill Development program on NX CAD

Department Mechanical Engineering organized a Skill Development program on NX CAD for third year students to enhance the knowledge on modeling software and this program will also improve the skill level of a student in modeling of components.

Workshops And Conferences

Eminent Speakers

Get In Touch

-

principal@rnsit.ac.in

principal@rnsit.ac.in

-

080 28611880/

1/

2,+91 90359 60355

080 28611880/

1/

2,+91 90359 60355

-

RNS Institute of Technology,

RNS Institute of Technology,

Dr. Vishnuvardhan Road

R R Nagar Post

Channasandra

Bengaluru -560 098

Send A Message